We use cookies to improve your online experience. By continuing browsing this website, we assume you agree our use of cookies.

La machine de moulage par compression est une forme avancée du moulage par injection traditionnel. La machine de moulage par compression du caoutchouc convient aux produits fabriqués à partir de divers plastiques techniques thermoplastiques. L'espace de la cavité du moule peut être ajusté automatiquement en fonction des différentes exigences.

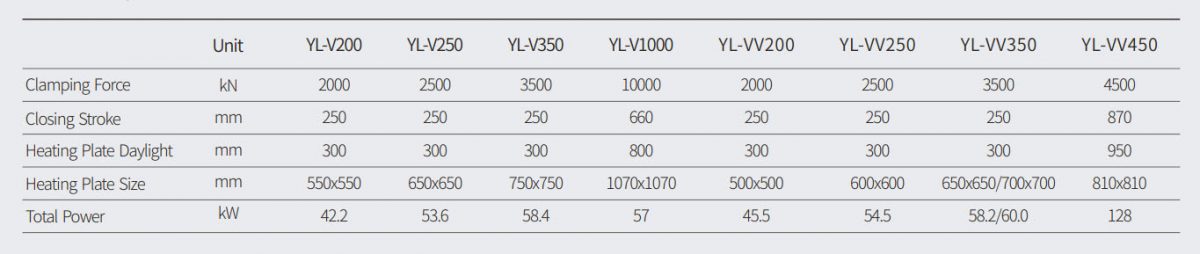

Série de machines de moulage par compression du caoutchouc

l Conception à faible consommation d'énergie, plaque isolante écologique à haute résistance

l La température du moule est maintenue pendant que la plaque chauffante glisse vers l'extérieur.

l Vitesse de course plus rapide.

l Système de contrôle Siemens.

l Composants électriques, hydrauliques et d'étanchéité de renommée internationale.

Yizumi is committed to creating a globally advanced manufacturing platform and providing a reliable guarantee for Production;

Yizumi has been deepening the transformation and upgrade of the company. Through the connection of advanced European molding technology, and the establishment of R&D center and innovation center in china and abroad, Yizumi always introduces internationally advanced technology to strengthen customer's competitiveness.

Yizumi rubber compression moulding machine manufacturer is committed to building an internationally advanced manufacturing platform with multiple processing equipment worth tens of millions of dollars. This platform includes "OKUMA", "TOSHIBA", "MORI SEIKI" and "MAZAK" from Japan,TOS heavy boring and milling machining center from Czech Republic. Yizumi provides a powerful guarantee for the processing of key parts.

To significantly improve product's components accuracy, processing accuracy, and assembly accuracy,Yizumi is equipped with Sophisticated original imported testing instruments and equipment,and always upholds high-quality standards.

Principaux Dispositifs à Option :

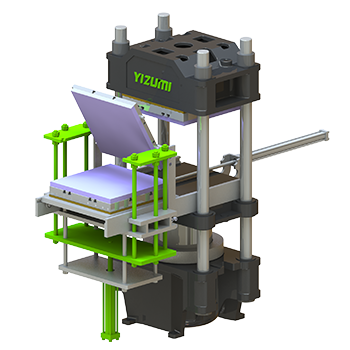

Dispositif de clipsage + dispositif glissant du moule inférieur

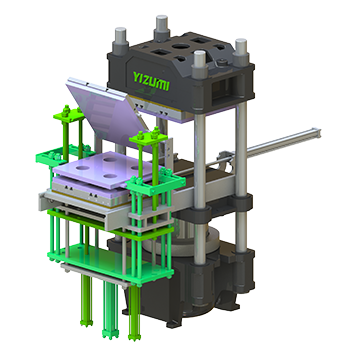

2RT + dispositif de basculement

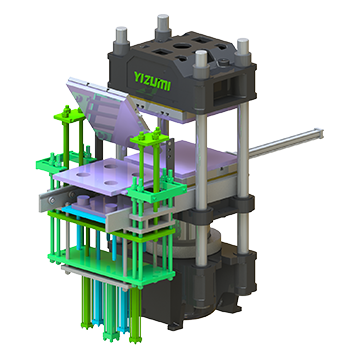

3RT double levage + dispositif de basculement

4RT + dispositif basculant