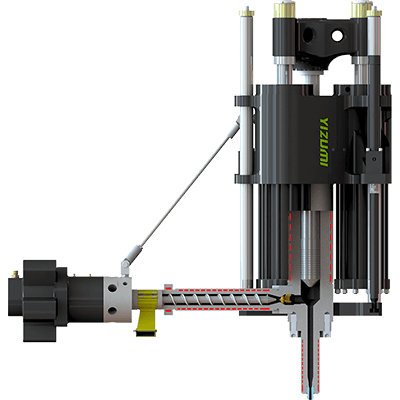

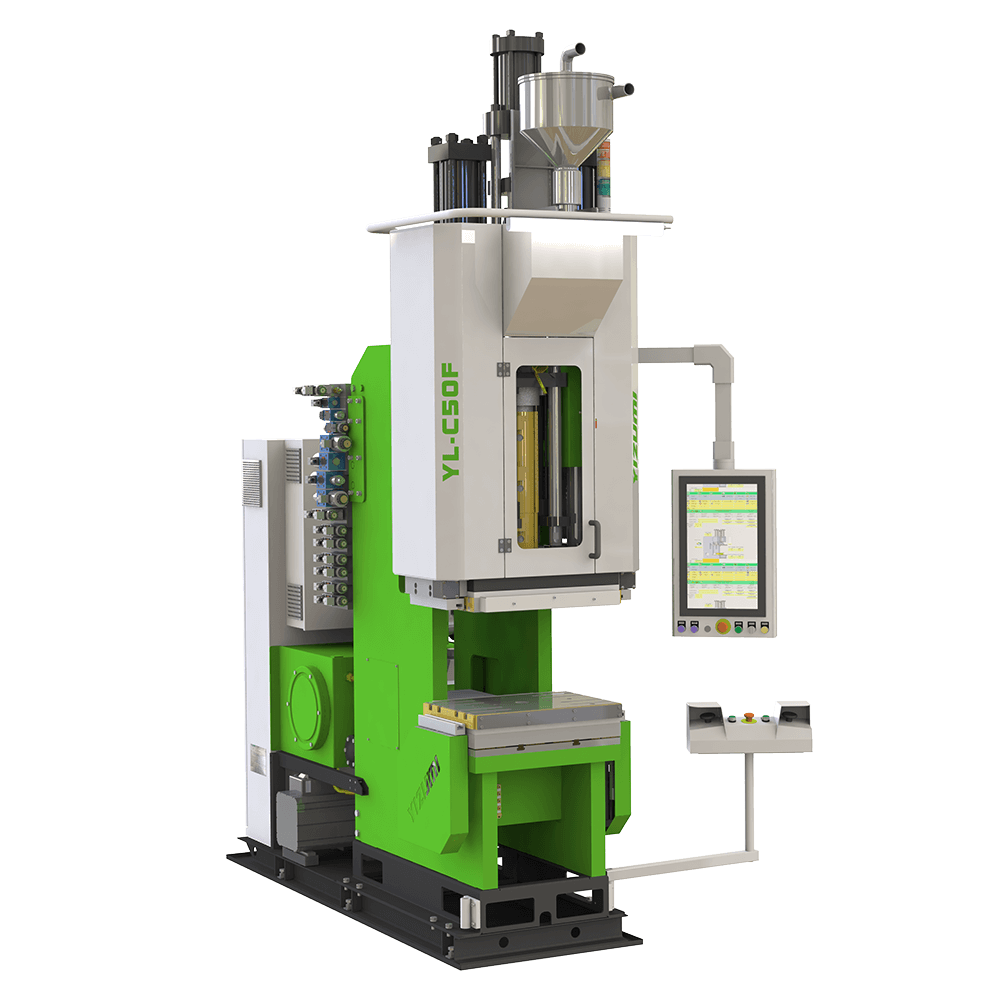

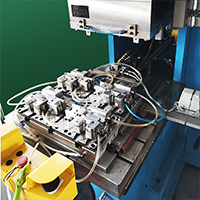

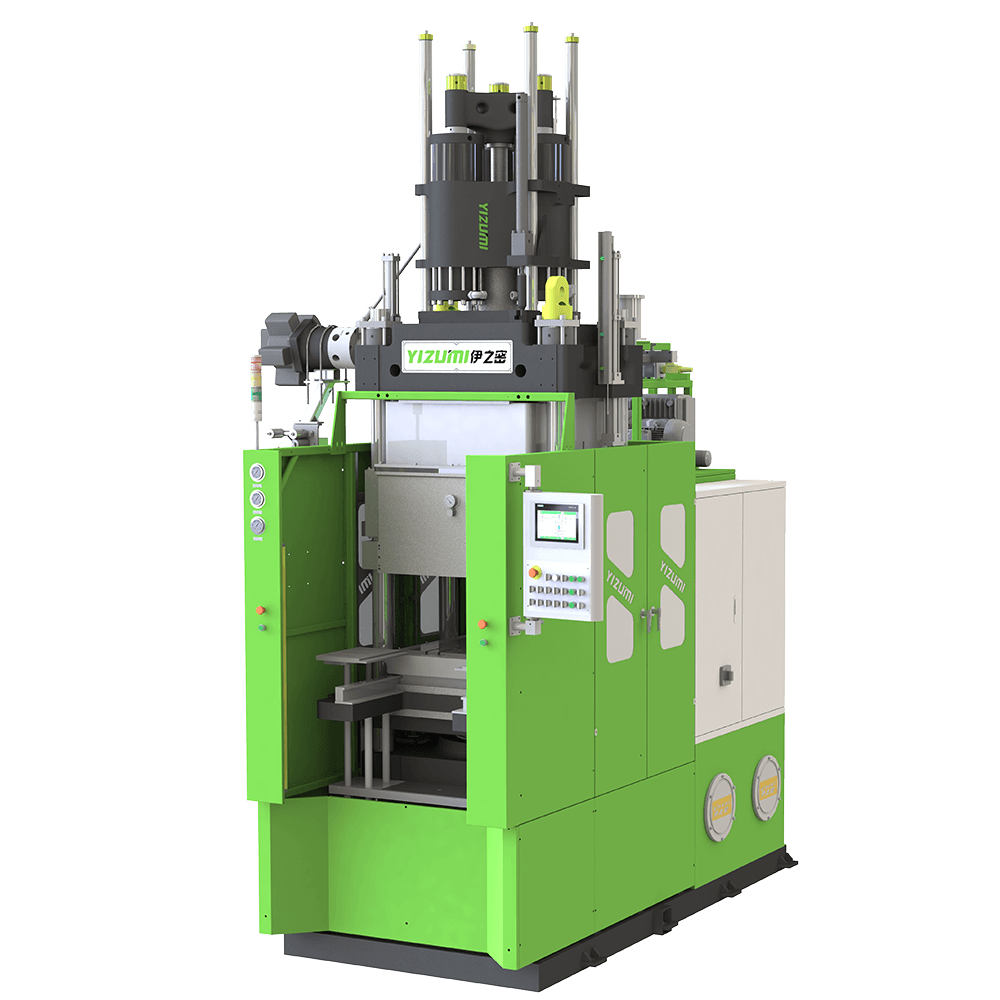

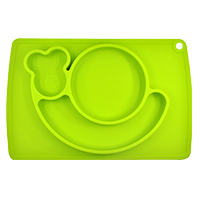

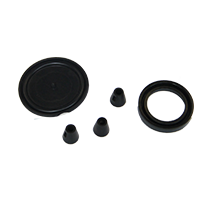

Yizumi Rubber Machinery Co., Ltd., a holding subsidiary of Yizumi Group, was founded in 2009 and has drafted two National Standards for the Rubber Injection Machine Industry. Yizumi rubber injection molding machine ranks among the forefront in China market with a wide range of applications for molding all kinds of rubber parts in automobile, energy, electronics, railway transportation, medical care, household appliances. combining advanced and comprehensive foundation technology from Yizumi group and considerable experience and specialized technology from the rubber machinery team, Yizumi can provide customized solutions to satisfy global customers' personalized needs.

Contact YIZUMIWe use cookies to improve your online experience. By continuing browsing this website, we assume you agree our use of cookies.

.jpg)

.jpg)

_(1).png)

.png)

.png)

.png)