We use cookies to improve your online experience. By continuing browsing this website, we assume you agree our use of cookies.

Brand:Yizumi

Original:Guangzhou,Foshan

Payment Terms: T/T,L/C,Paypal,Western Union

Delivery Time: Negotiate

Certificate: CE,ISO9001

OEM/ODM: Accepted

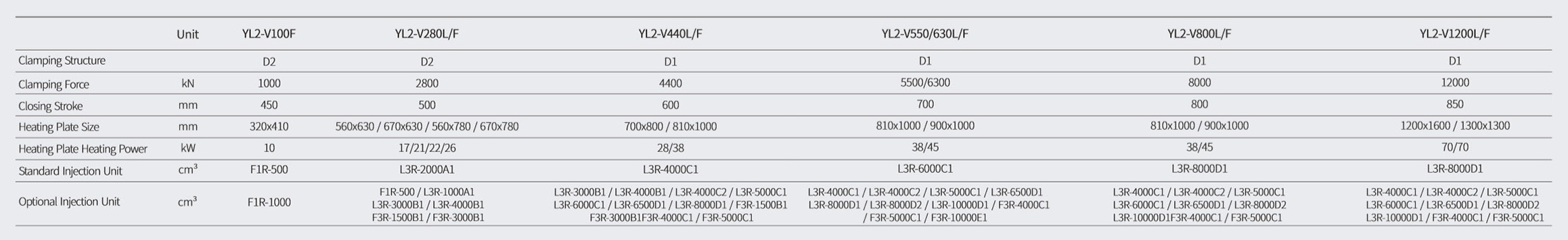

Model: YL3-V440L,V100F,V280L,V630F,V1200L

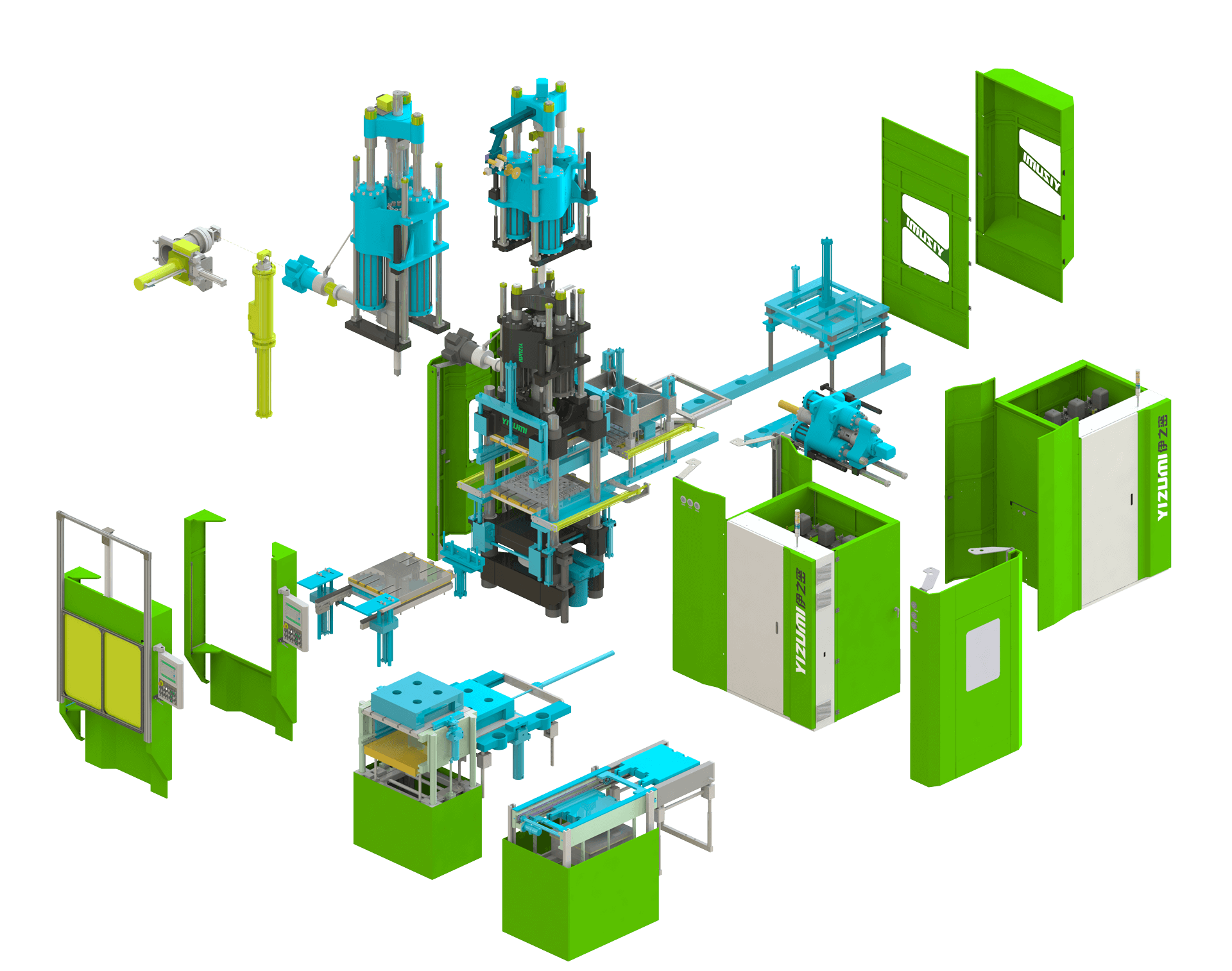

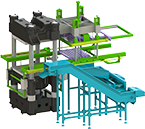

YL3-VL/F is the 3rd Generation European Series Fully Automatic Injection Moulding Machine

It is an intelligent machine that meets requirements of Industry 4.0 for rubber industry. The Fully Automatic Injection Moulding Machine uses new core technology, more precise and reliable, and has “smart” components. Simple operation, less maintenance and easy management. More comprehensive and accurate data supports intelligent manufacturing, thereby helps customers easily reach their business goals.

Yizumi is committed to creating a globally advanced manufacturing platform and providing a reliable guarantee for Production;

Yizumi has been deepening the transformation and upgrade of the company. through the connection of advanced European molding technology, and the establishment of R&D center and innovation center in china and abroad, Yizumi always introduces internationally advanced technology to strengthen customer's competitiveness.

Yizumi is committed to building an internationally advanced manufacturing platform with multiple processing equipment worth tens of millions of dollars. This platform includes "OKUMA", "TOSHIBA", "MORI SEIKI" and "MAZAK" from Japan,TOS heavy boring and milling machining center from Czech Republic. Yizumi provides a powerful guarantee for the processing of key parts.

To significantly improve product's components accuracy, processing accuracy, and assembly accuracy,Yizumi is equipped with Sophisticated original imported testing instruments and equipment,and always upholds high-quality standards.

Meeting the mainstream European mold installation and demolding requirements. Dozens of precise modules, flexible combination. One set of advanced software, simple editing. All these quickly meet diverse needs.

① Open gate silicone stuffer

② Side open silicone stuffer

③ Injection piston damper device

④ L3R Injection unit (non-standard injection volume)

⑤ F3R injection unit

⑥ Strip compound feeding device

⑦ Top hydraulic mold separator

⑧ Bottom hydraulic mold separator

⑨ Center Ejector

⑩ Lower mold sliding device

⑪ 2RT

⑫ Rear side downward ejecting device

⑬ Auto ejecting device for bushing

⑭ Double lower or middle mold non-synchronic exchange (suitable for thick mold)

⑮ Double lower or middle mold synchronic exchange

⑯ B & R control system with 10'' touch screen or siemens control system with 9'' HD screen

⑰ Pneumatic door

⑱ F3R 2nd injection unit (two compounds)

⑲ Oil tank at rear side(not for 100T and 280T)

⑳ Robotic system

㉑ Manual double middle mold exchange device

㉒ Regular motor + variable displacement pump

Piston can be fully pulled out for quick cleaning without removing bolts.

Downward automatic ejector, suitable for bushings or similar products, products can betransported to the front ofmachine through conveyor. belt, convenient for product checking

Synchronic mold exchange, outer mold has dedicated heating plate, suitable for thin mold which needs long demolding time.

Vetical Side Plate Clamping Structyre Vetical Side Plate Clamping Structyre