We use cookies to improve your online experience. By continuing browsing this website, we assume you agree our use of cookies.

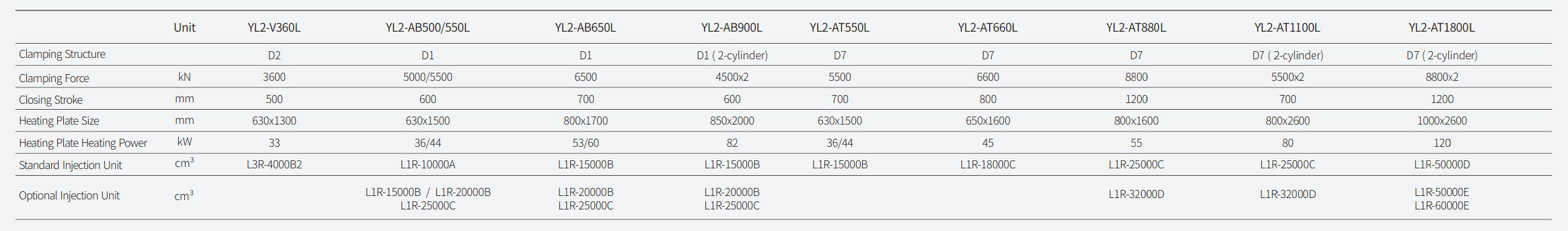

Special injection molding machine YL2-ABL series adopts D1 upward clamping structure, which is relatively cost-effective.

Injection molding machine YL2-ATL series adopts D7 downward mold closing structure, which has more advantages for products that need multiple-step molding; at the same time, silicone stuffer is installed on the ground level, silicone block can be easily dropped inside.

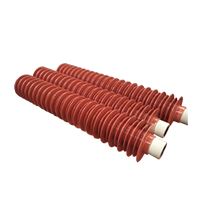

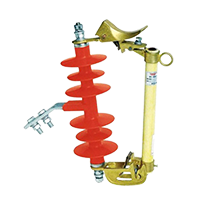

Injection molding machine YL-H1000F is terrific for molding UHV hollow core insulator. It can efficiently produce hollow core insulators free of defects such as air bubble, heavy flash, non-filling. It adopts low pressure injection molding technology to protect FRP tubes. Its ease of operation, production efficiency and product quality are perfect.

Injection molding machine YL-H1000F is terrific for molding UHV hollow core insulator. It can efficiently produce hollow core insulators free of defects such as air bubble, heavy flash, non-filling. It adopts low pressure injection molding technology to protect FRP tubes. Its ease of operation, production efficiency and product quality are perfect.

Yizumi injection molding machine supplier is committed to creating a globally advanced manufacturing platform and providing a reliable guarantee for Production;

Yizumi has been deepening the transformation and upgrade of the company. through the connection of advanced European molding technology, and the establishment of R&D center and innovation center in china and abroad, Yizumi injection molding machine supplier always introduces internationally advanced technology to strengthen customer's competitiveness.

Yizumi is committed to building an internationally advanced manufacturing platform with multiple processing equipment worth tens of millions of dollars. This platform includes "OKUMA", "TOSHIBA", "MORI SEIKI" and "MAZAK" from Japan,TOS heavy boring and milling machining center from Czech Republic. Yizumi injection molding machine supplier provides a powerful guarantee for the processing of key parts.

To significantly improve product's components accuracy, processing accuracy, and assembly accuracy,Yizumi is equipped with Sophisticated original imported testing instruments and equipment,and always upholds high-quality standards.

Vetical Side Plate Clamping Structyre Vetical Side Plate Clamping Structyre