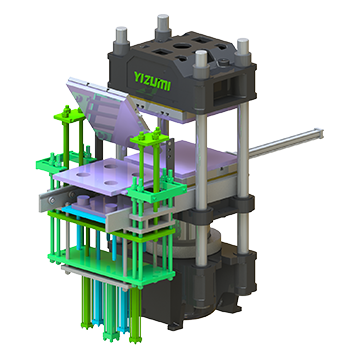

We use cookies to improve your online experience. By continuing browsing this website, we assume you agree our use of cookies.

Low energy consumption design, high strength environmental friendly insulation plate

Mold temperature maintained while heating plate sliding out

Faster running speed

Siemens control system

International well-known electrical, hydraulic and sealing components

Yizumi is committed to creating a globally advanced manufacturing platform and providing a reliable guarantee for Production;

Yizumi has been deepening the transformation and upgrade of the company. Through the connection of advanced European molding technology, and the establishment of R&D center and innovation center in china and abroad, Yizumi always introduces internationally advanced technology to strengthen customer's competitiveness.

Yizumi rubber compression moulding machine manufacturer is committed to building an internationally advanced manufacturing platform with multiple processing equipment worth tens of millions of dollars. This platform includes "OKUMA", "TOSHIBA", "MORI SEIKI" and "MAZAK" from Japan,TOS heavy boring and milling machining center from Czech Republic. Yizumi provides a powerful guarantee for the processing of key parts.

To significantly improve product's components accuracy, processing accuracy, and assembly accuracy,Yizumi is equipped with Sophisticated original imported testing instruments and equipment,and always upholds high-quality standards.

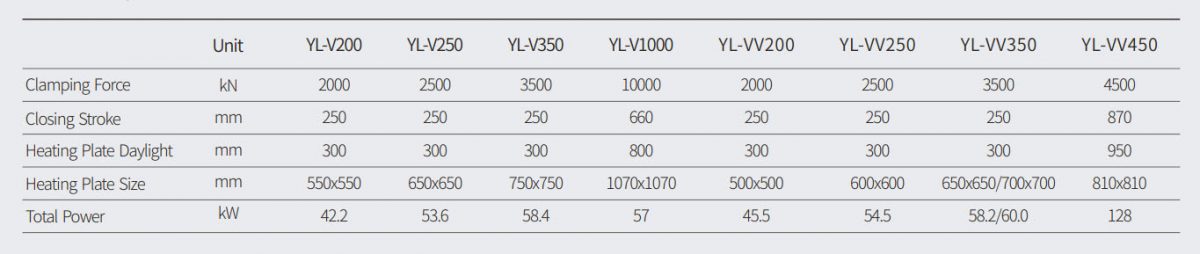

Clipping device + lower mold sliding device

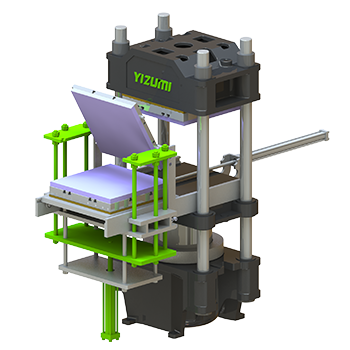

2RT + tilting device

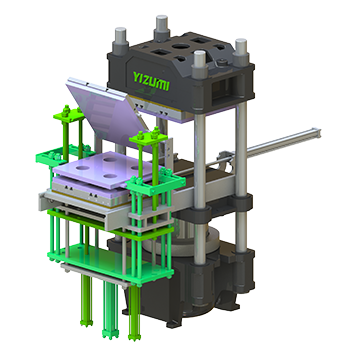

3RT double lifter + tilting device

4RT + tilting device