We use cookies to improve your online experience. By continuing browsing this website, we assume you agree our use of cookies.

YL3-VL/F Asian Series Injection Machine

Integrated with the latest rubber injection molding technology, and CBB of YIZUMI, the A3 series machines have been greatly optimized and upgraded in terms of molding performance, reliability, ease of use, maintainability and life cycle. Make it the premier choice for intelligent manufacturing of rubber parts.

① KEBA control system, 15’’ touch screen, V4.3 software;

② Yizumi 4th generation energy-efficient servo technology;

③ External F.I.F.O plasticizing injection unit;

④ Top hydraulic mold separator;

⑤ GB safety standard.

250T and 350T both with oil tank at the rear side or on the right side

Yizumi is committed to creating a globally advanced manufacturing platform and providing a reliable guarantee for Production;

Yizumi has been deepening the transformation and upgrade of the company. through the connection of advanced European molding technology, and the establishment of R&D center and innovation center in china and abroad, Yizumi always introduces internationally advanced technology to strengthen customer's competitiveness.

Yizumi is committed to building an internationally advanced manufacturing platform with multiple processing equipment worth tens of millions of dollars. This platform includes "OKUMA", "TOSHIBA", "MORI SEIKI" and "MAZAK" from Japan,TOS heavy boring and milling machining center from Czech Republic. Yizumi provides a powerful guarantee for the processing of key parts.

To significantly improve product's components accuracy, processing accuracy, and assembly accuracy,Yizumi is equipped with Sophisticated original imported testing instruments and equipment,and always upholds high-quality standards.

Establish customer files and provide consulting and guidance services through the return visit mechanism.

2、On Site CheckingService engineer will check the machine regularly and provide preventive maintenance.

3、Spare Partswe provide customers with a convenient spare part supply network to ensure the smooth,timely and accurate delivery of spare parts.

4、TrainingCarry out targeted training for professionals and customers.

5、Rating EvaluationWe conduct service rating certification for YFO service engineers and strictly regulate service standards.

6、24hrs Service365 days,24 hours exclusive hotline, maintenance experts to respond to your needs.

Service Networks and Spare Parts Centers Worldwide

YFO service network covers 76 cites in china and 39 out of china.

Spare parts stores across 53 cites in china and 23 out of china.

Part same-day delivery rate at headquarters≥96%

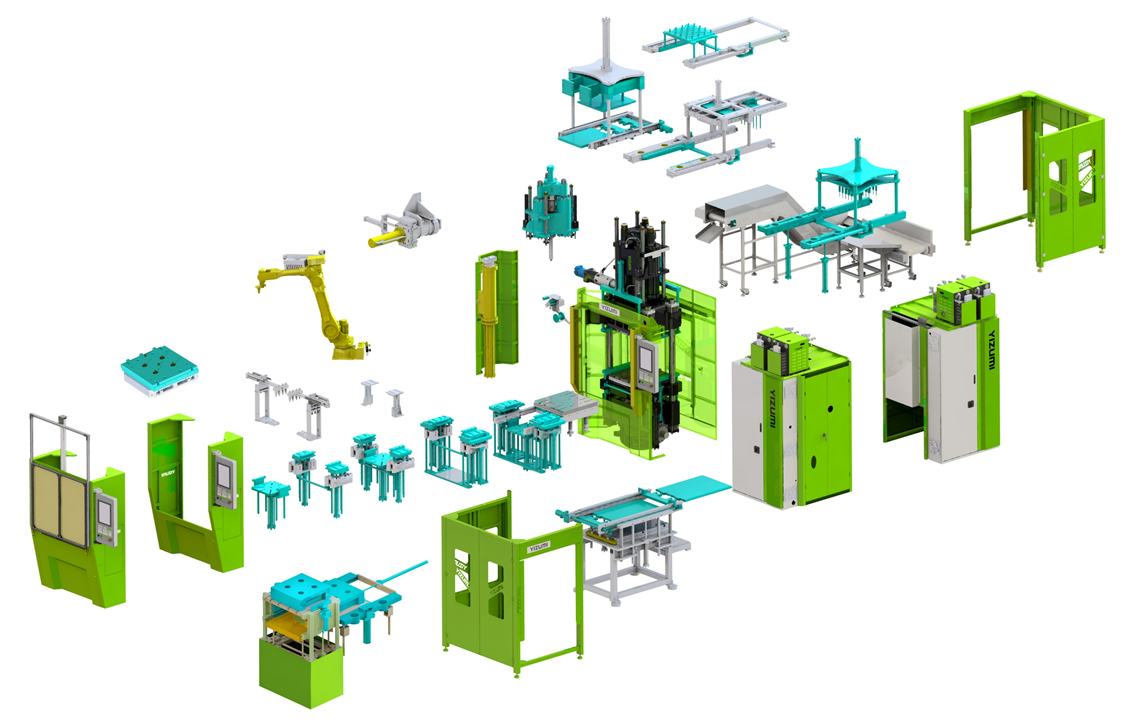

Smart And Diversified

Modular design makes the A3 series vertical rubber machine more flexible and inclusive. It can reliably and quickly meet the personalized needs of global customers for different products and processes, and is the best solution for customer production. Machine can be easily upgraded to a more automated, intelligent system with less manpower to empower advanced production.

Main Option Device

|

① Open gate silicone stuffer ② Side open silicone stuffer ③ EF3R unit ④ IF3R unit ⑤ Strip feeding device ⑥ Top hydraulic mold separator ⑦ Bottom hydraulic mold separator ⑧ Lower mold sliding device ⑨ 4RT ⑩ 3RT double lifter ⑪ 3RT with one ejector and one lifter ⑫ 2RT with one lifter ⑬ Knock down device ⑭ Double lower/middle mold synchronic exchange (suitable for thin mold) ⑮ Pneumatic door

|

⑯ B&R control system with 10” screen ⑰ B&R control system with 21” screen, V5 control and management system ⑱ CRB ⑲ CRB oil temperature control unit ⑳ Mechanical clipping device ㉑ Knock up device in clamping area ㉒ Rear sliding with half mold extraction ㉓ Non-integrated rear sliding with knock down device ㉔ 2RT with one ejector ㉕ Side core puller ㉖ Double lower/middle mold synchronic exchange (suitable for thick mold) ㉗ Conveyor ㉘ Robot arm

|

Vetical Side Plate Clamping Structyre Vetical Side Plate Clamping Structyre