We use cookies to improve your online experience. By continuing browsing this website, we assume you agree our use of cookies.

Machine de moulage par injection de caoutchouc de la châssis C

Des unités d’injection de haute précision et de faible volume pour le plastique, le caoutchouc et le LSR sont disponibles, particulièrement adaptées à la production de petites pièces précises avec inserts et assemblage de profilés.

Configuration Standard:

①Système de contrôle B & R avec écran 10”

②Affichage et contrôle de la vitesse de la vis

③Contrôle numérique proportionnel sensible de la contre-pression

④Alarme de manque matière

⑤Norme de sécurité CE

⑥Le système de gestion de l'énergie et de la température de 3ème génération

⑦Structure de fermeture D4

Principaux Dispositifs à Option :

①F1L-Unité d’injection LSR

②F1P-Unité d’injection plastique

③S1R-Unité d’injection de caoutchouc

④Éjecteur central

⑤Dispositif glissant

⑥Séparateur de moule hydraulique inférieur

⑦Séparateur de moule hydraulique supérieur

⑧Système d’échange à double moule inférieur (gauche-droit)

⑨Système rotatif à double moule inférieur

⑩Système de contrôle B & R avec l’écran tactile 21.5”

⑪Servo-vanne en boucle fermée qui contrôle la précision de l’injection

⑫Fonction de préchauffage de l’huile hydraulique

Yizumi is committed to creating a globally advanced manufacturing platform and providing a reliable guarantee for Production;

Yizumi has been deepening the transformation and upgrade of the company. through the connection of advanced European molding technology, and the establishment of R&D center and innovation center in china and abroad, Yizumi always introduces internationally advanced technology to strengthen customer's competitiveness.

Yizumi is committed to building an internationally advanced manufacturing platform with multiple processing equipment worth tens of millions of dollars. This platform includes "OKUMA", "TOSHIBA", "MORI SEIKI" and "MAZAK" from Japan,TOS heavy boring and milling machining center from Czech Republic. Yizumi provides a powerful guarantee for the processing of key parts.

To significantly improve product's components accuracy, processing accuracy, and assembly accuracy,Yizumi is equipped with Sophisticated original imported testing instruments and equipment,and always upholds high-quality standards.

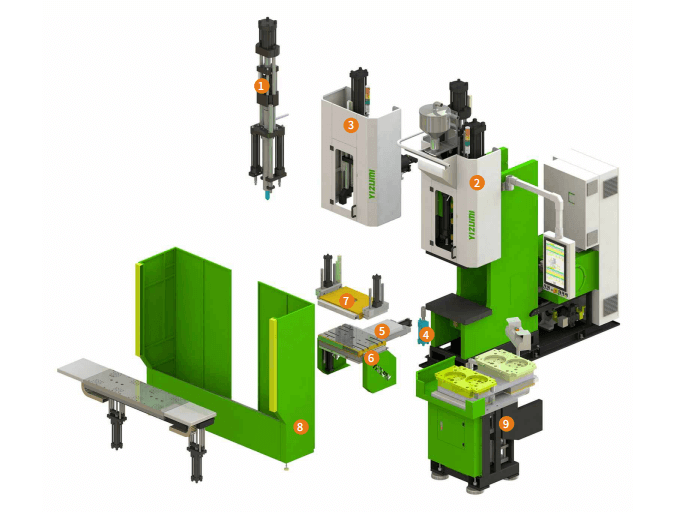

① F1L-LSR injection unit

② F1P-Plastic injection unit

③ S1R-Rubber injection unit

④ Center ejector

⑤ Sliding device

⑥ Bottom hydraulic mold separator

⑦ Top hydraulic mold separator

⑧ Double lower mold exchange system(left-right)

⑨ Double lower mold rotary system

⑩ B&R control system with 21.5'' touch screen

⑪ Closed-loop servo valve controls injection accuracy

⑫ Preheating function of hydraulic oil

Vetical Side Plate Clamping Structyre Vetical Side Plate Clamping Structyre